A completely new research in contrast the results of the keto diet program along with a food plan low in additional sugars and located the keto diet plan was related to lifted "terrible" cholesterol…

Although issues which include product or service sensitivity and contamination hazards persist, study and adherence to stringent protocols mitigate these worries, ensuring the security and efficacy of lyophilized pharmaceuticals.

This video clip demonstrates how the FreeZone Triad Benchtop Freeze Dryer is created to lyophilize the widest range of sample types: from bulk things, vials and microplates on heated shelves to large samples in flasks.

Last of all, the product or service goes through a chemical pre-treatment method that adjusts its pH and/or adds fillers for instance mannitol to boost the dry weight of the products cake

Furthermore, it describes the application of CFD coupled with mathematical modeling in the lyophilization process and solution advancement, scale-up, and producing. On top of that, Rules and Follow of Lyophilization Process and Merchandise Development consists of a complete focused part on “Preservation of Biologicals” comprised of nine chapters written by experts and like situation scientific tests. Comparable content becoming seen by Other individuals

This is a preview of membership written content, log in by using an establishment to check access. Accessibility this ebook

These partly stoppered vials are transported towards the lyophilizer and loaded in below aseptic conditions

Here read more are several uncomplicated suggestions to obtain the ideal effects when freeze drying. These tips might also assist you keep away from breaking glassware, and assistance you choose the very best technique of freeze dry preparing.

The inspection phase is the final phase of the lyophilization process, along with the product or service is now more info all set to be packaged and transported to the right client.

Fecal samples have been gathered from healthier, inflammatory bowel disorder, and irritable bowel syndrome clients with the 1st Department of Pediatrics, Semmelweis University. Specimens were being saved refrigerated up to 24 h, then aliquoted and saved frozen at −80 °C right up until more use.

Kobayashi M. Progress of a completely new refrigeration system and optimum geometry of the vapor condenser for pharmaceutical freeze dryers. In: Proceedings from the 4th Intercontinental drying symposium. Kyoto, Japan; 1984.

Lyophilization is usually a significant process in the sterile fill-complete phase of pharmaceutical production, significantly for products that need superior levels of steadiness and a longer shelf existence. The freeze-drying approach requires taking away drinking water from a frozen drug product or service underneath low temperature and vacuum with no compromising its structural integrity and efficacy.

have one or more cryogenic tanks, also referred to as dewars, Positioned within or outside their making. These dewars contain the needed liquid nitrogen.

Firstly of the main drying section, ice sublimation usually takes spot within the solution area. As being the process continues, the subliming surface area withdraws in to the merchandise as well as the ensuing vapor need to be conducted throughout the Earlier dried outer levels.

Jake Lloyd Then & Now!

Jake Lloyd Then & Now! Brian Bonsall Then & Now!

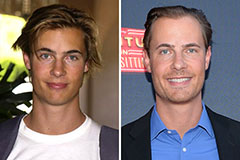

Brian Bonsall Then & Now! Erik von Detten Then & Now!

Erik von Detten Then & Now! Lynda Carter Then & Now!

Lynda Carter Then & Now! Christy Canyon Then & Now!

Christy Canyon Then & Now!